BRISBANE, Australia, Aug. 02, 2023 (GLOBE NEWSWIRE) -- Allkem Limited (ASX|TSX: AKE, “Allkem” or the “Company”) is pleased to provide a drilling update for its James Bay Lithium Project in Québec, Canada.

HIGHLIGHTS

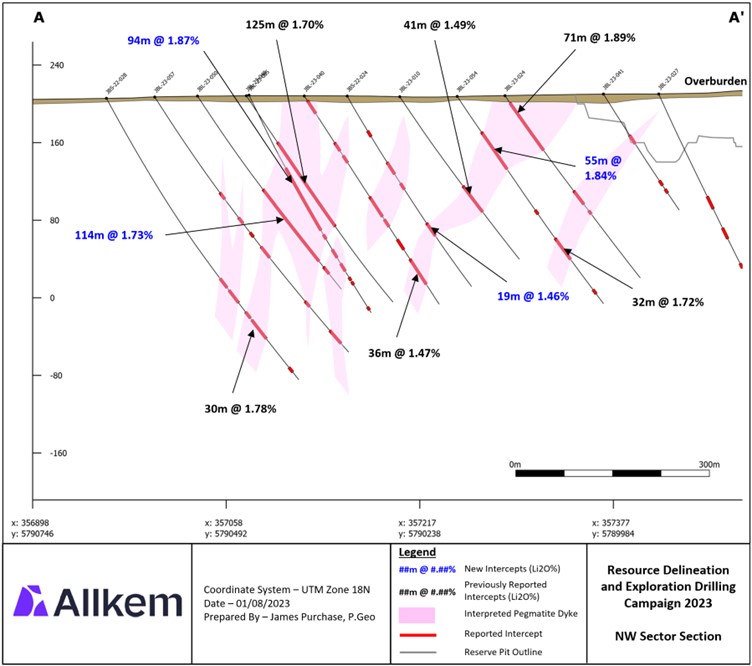

- Assays continue to demonstrate thick intercepts of lithium mineralisation within spodumene-bearing pegmatites in the NW Sector.

- Intercepts include 114m @ 1.73 % Li2O from 140.5m in JBL-23-050, and 94m @ 1.87 % Li2O from 107m in JBL-23-085. The reader is cautioned that these thicknesses represent downhole thicknesses and not true thicknesses. True thicknesses are estimated to be between 60% and 80% of downhole thicknesses.

RESOURCE DELINEATION DRILLING

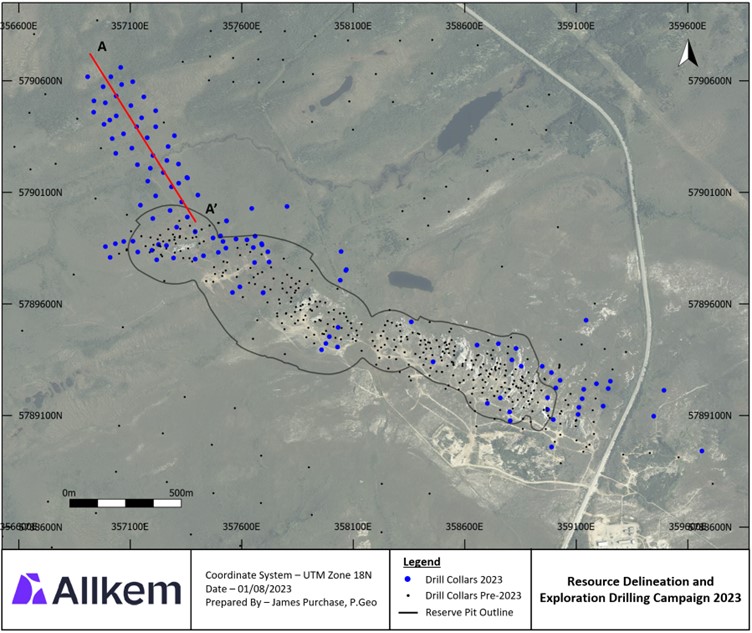

Between December 2022 and April 2023, Allkem undertook a resource definition drilling campaign with the aim of delineating the pegmatite dykes around the extremities of the deposit, and to test for strike extensions to the north-west. In total, 130 drill holes were completed for a total meterage of 29,124m. A significant portion of this drilling was designed to support a maiden Inferred Mineral Resource in the NW Sector, supported by an 80m x 80m drilling pattern.

Interim assay results relating to the newly discovered NW Sector were announced to the market on May 4th, 2023. The remaining assays have been received from the laboratory and are included in this announcement with a supporting plan view (Figure 1) and schematic section (Figure 2).

Assay highlights for the remaining assays from the 2023 drilling campaign include:

| Drillhole | From (m) | To (m) | Downhole Thickness (m) | Estimated True Thickness (m) | Li2O% |

JBL-23-002

| 42.0 | 124.0 | 82.0 | 74.7 | 1.52 |

| 267.7 | 305.9 | 38.2 | 33.6 | 1.42 |

| JBL-23-003 | 113.0 | 149.7 | 36.7 | 28.5 | 1.54 |

| JBL-23-036 | 191.0 | 224.0 | 33.0 | 29.3 | 1.35 |

JBL-23-043

| 311.5 | 345.2 | 33.7 | 27.8 | 1.72 |

| 438.0 | 480.5 | 42.5 | 34.4 | 1.48 |

| JBL-23-0501 | 140.5 | 254.8 | 114.3 | 79.8 | 1.73 |

| JBL-23-054 | 52.7 | 107.7 | 55.0 | 48.2 | 1.84 |

| JBL-23-081 | 292.3 | 338.7 | 46.4 | 29.6 | 1.80 |

JBL-23-082

| 178.0 | 217.5 | 39.5 | 26.4 | 1.67 |

| 289.4 | 369.1 | 79.7 | 52.1 | 1.64 |

| JBL-23-083 | 108.7 | 152.4 | 43.8 | 38.4 | 1.77 |

| JBL-23-085 | 107.0 | 201.1 | 94.1 | 84.5 | 1.87 |

- Partial assays released on May 4th 2023.1

Managing Director and CEO, Martin Perez de Solay said, “These outstanding drilling results confirm a material extension of mineralisation at James Bay. Work is now focussed on reviewing the Mineral Resource to include the additional results from the 2023 drilling program and an update is expected by the end of the month.

“James Bay is a Tier 1 lithium asset with the potential to grow even further as the boundaries of mineralisation are tested through an additional drilling program commencing later in the year."

Figure 1: James Bay 2023 drilling program – Plan view of drill collars

All drillhole collars from the 2023 drilling campaign are tabulated in Appendix 2, and all new significant assay intervals received since the May 4th 2023 announcement are presented in Appendix 3.

Figure 2: NW Sector cross section, looking north-east.

NEXT STEPS

A Mineral Resource update is on-track for completion in August 2023, and will be announced to the market once internal checks and verifications are complete.

The Company is currently planning a significant diamond drilling campaign to start in November 2023 to expand on the additional lithium-bearing pegmatites discovered last winter. The drilling program will consist of both in-fill drilling to better understand the geometry of the pegmatites, and step-out exploration drilling to discover new pegmatites along-strike to the NW zone.

This release was authorised by Mr Martin Perez de Solay, CEO and Managing Director of Allkem Limited.

IMPORTANT NOTICES

This investor ASX/TSX release (Release) has been prepared by Allkem Limited (ACN 112 589 910) (the Company or Allkem). It contains general information about the Company as at the date of this Release. The information in this Release should not be considered to be comprehensive or to comprise all of the material which a shareholder or potential investor in the Company may require in order to determine whether to deal in Shares of Allkem. The information in this Release is of a general nature only and does not purport to be complete. It should be read in conjunction with the Company’s periodic and continuous disclosure announcements which are available at allkem.co and with the Australian Securities Exchange (ASX) announcements, which are available at www.asx.com.au.

This Release does not take into account the financial situation, investment objectives, tax situation or particular needs of any person and nothing contained in this Release constitutes investment, legal, tax, accounting or other advice, nor does it contain all the information which would be required in a disclosure document or prospectus prepared in accordance with the requirements of the Corporations Act 2001 (Cth) (Corporations Act). Readers or recipients of this Release should, before making any decisions in relation to their investment or potential investment in the Company, consider the appropriateness of the information having regard to their own individual investment objectives and financial situation and seek their own professional investment, legal, taxation and accounting advice appropriate to their particular circumstances.

This Release does not constitute or form part of any offer, invitation, solicitation or recommendation to acquire, purchase, subscribe for, sell or otherwise dispose of, or issue, any Shares or any other financial product. Further, this Release does not constitute financial product, investment advice (nor tax, accounting or legal advice) or recommendation, nor shall it or any part of it or the fact of its distribution form the basis of, or be relied on in connection with, any contract or investment decision.

The distribution of this Release in other jurisdictions outside Australia may also be restricted by law and any restrictions should be observed. Any failure to comply with such restrictions may constitute a violation of applicable securities laws.

Past performance information given in this Release is given for illustrative purposes only and should not be relied upon as (and is not) an indication of future performance.

Forward Looking Statements

Forward-looking statements are based on current expectations and beliefs and, by their nature, are subject to a number of known and unknown risks and uncertainties that could cause the actual results, performances and achievements to differ materially from any expected future results, performances or achievements expressed or implied by such forward-looking statements, including but not limited to, the risk of further changes in government regulations, policies or legislation; the risks associated with the continued implementation of the merger between the Company and Galaxy Resources Ltd, risks that further funding may be required, but unavailable, for the ongoing development of the Company’s projects; fluctuations or decreases in commodity prices; uncertainty in the estimation, economic viability, recoverability and processing of mineral resources; risks associated with development of the Company Projects; unexpected capital or operating cost increases; uncertainty of meeting anticipated program milestones at the Company’s Projects; risks associated with investment in publicly listed companies, such as the Company; and risks associated with general economic conditions.

Subject to any continuing obligation under applicable law or relevant listing rules of the ASX, the Company disclaims any obligation or undertaking to disseminate any updates or revisions to any forward-looking statements in this Release to reflect any change in expectations in relation to any forward-looking statements or any change in events, conditions or circumstances on which any such statements are based. Nothing in this Release shall under any circumstances (including by reason of this Release remaining available and not being superseded or replaced by any other Release or publication with respect to the subject matter of this Release), create an implication that there has been no change in the affairs of the Company since the date of this Release.

Competent Person Statement

The information in this announcement that relates to Exploration Results is based on information compiled by James Purchase, P.Geo, MAusIMM (CP), a Competent Person who is both a member of L’Ordre des Géologues du Québec (License No. 2082) and a Member of The Australasian Institute of Mining and Metallurgy (with Chartered Professional status). Mr. Purchase is a full-time employee of Galaxy Lithium (Canada) Inc. Mr. Purchase has sufficient experience that is relevant to the style of mineralization and type of deposit under consideration and to the activity being undertaken to qualify as a Competent Person as defined in the 2012 Edition of the ‘Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves’. Mr. Purchase consents to the inclusion in this announcement of the matters based on his information in the form and context in which it appears.

Notforreleaseordistribution in theUnited States

This announcement has been prepared for publication in Australia and may not be released to U.S. wire services or distributed in the United States. This announcement does not constitute an offer to sell, or a solicitation of an offer to buy, securities in the United States or any other jurisdiction, and neither this announcement or anything attached to this announcement shall form the basis of any contract or commitment. Any securities described in this announcement have not been, and will not be, registered under the U.S. Securities Act of 1933 and may not be offered or sold in the United States except in transactions registered under the U.S. Securities Act of 1933 or exempt from, or not subject to, the registration of the U.S. Securities Act of 1933 and applicable U.S. state securities laws.

APPENDIX 1 – JORC 2012 TABLE 1 DISCLOSURE

Section 1: Sampling Techniques and Data

| JAMES BAY LITHIUM PROJECT SAMPLING AND DATA |

| Sampling techniques | | Nature and quality of sampling (e.g. cut channels, random chips, or specific specialized industry standard measurement tools appropriate to the minerals under investigation, such as down hole gamma sondes, or handheld XRF instruments, etc.). These examples should not be taken as limiting the broad meaning of sampling.

Include reference to measures taken to ensure sample representivity and the appropriate calibration of any measurement tools or systems used.

Aspects of the determination of mineralization that are Material to the Public Report.

In cases where ‘industry standard’ work has been done this would be relatively simple (e.g. ‘reverse circulation drilling was used to obtain 1 m samples from which 3 kg was pulverized to produce a 30 g charge for fire assay’). In other cases, more explanation may be required, such as where there is coarse gold that has inherent sampling problems. Unusual commodities or mineralization types (e.g. submarine nodules) may warrant disclosure of detailed information. | | 2008/2009 Exploration Drilling – Lithium One

Lithium One (subsequently acquired by Galaxy Lithium (Canada) Inc.) drilled a total of 102 diamond drill holes for 13,487m on a pattern ranging between 50m and 60m spacing. Drill holes were for the most part inclined towards the south-east to intersect the spodumene mineralization perpendicular to the dyke geometry. Drillhole diameter was NQ.

The 2008/2009 drill-hole collars were initially surveyed by handheld GPS, and subsequently resurveyed using RTK by Galaxy Lithium Canada in 2017. A total of 84 out of 102 drill holes were located and resurveyed by RTK.

Downhole survey methods for the 2008 drilling are unknown, however downhole surveying in 2009 was conducted at 3m intervals using a REFLEX Flexit tool.

2009/2010 Channel Sampling – Lithium One

Surface outcrops of pegmatite were channel sampled in 2009 and 2010 using a dual-blade diamond saw to ensure consistent widths during cutting. A total of 53 channel samples were collected for a combined length of 810m. Channel lengths ranged from 2m to 41m, and sampling was conducted on 1.5m intervals. Channel samples were terminated at the contact with surrounding lithologies.

2017 Resource Definition Drilling – Galaxy Lithium (Canada) Inc.

Galaxy Lithium (Canada) Inc. conducted a program of infill and extensional diamond drilling in 2017 with 157 holes drilled for a total meterage of 33,339m. Drillhole diameter was NQ. All drill hole collars were resurveyed using a RTK method. Downhole surveys were recorded every 3m using a multi-shot camera (REFLEX EZ-TRAC).

2017/2018 Geotech and Metallurgical Drilling – Galaxy Lithium (Canada) Inc.

Galaxy Lithium (Canada) Inc. conducted a program of diamond drilling in 2017 and 2018, with 102 holes drilled for a total meterage of 10,900m. Drillhole diameter was HQ for metallurgical drill holes, and NQ for the remaining Geotech holes.

2021 - 2023 Sterilisation, Exploration and Resource Delineation Drilling – Galaxy Lithium (Canada) Inc.

Galaxy Lithium (Canada) Inc. conducted two programs of diamond drilling during the winter of 2021/2022 and 2022/2023, with 231 holes drilled for a total meterage of 43,600m. Drillhole diameter was NQ and drilling was undertaker by Major Drilling. All drill hole collars were resurveyed using a RTK method by an independent land surveyor. Downhole surveys were recorded every 3m using a multi-shot camera (REFLEX EZ-TRAC) or a gyroscope. |

| Drilling techniques | | Drill type (e.g. core, reverse circulation, open-hole hammer, rotary air blast, auger, Bangka, sonic, etc.) and details (e.g. core diameter, triple or standard tube, depth of diamond tails, face-sampling bit or other type, whether core is oriented and if so, by what method, etc.). | | Diamond Drilling:

Drilling campaigns between 2008 and 2018 were conducted by Chibougamou Drilling using either NQ or HQ drilling diameters. Triple tubing was not necessary as the rock is fresh and highly competent starting from the base of the overburden. Recoveries were excellent (> 95%).

Drilling campaigns conducted between 2021 and 2023 were carried out by Major Drilling using NQ drill diameter.

Exploration and resource definition drillholes vary in depth from 50m to 300m, with the occasional deep exploration hole up to 500m depth.

Metallurgical drillholes are HQ diameter and vary in depth between 10m and 105m.

Geotech and sterilisation drillholes are NQ diameter and are generally 70m to 120m deep. |

| Logging | | Whether core and chip samples have been geologically and geotechnically logged to a level of detail to support appropriate Mineral Resource estimation, mining studies and metallurgical studies.

Whether logging is qualitative or quantitative in nature. Core (or costean, channel, etc.) photography.

The total length and percentage of the relevant intersections logged. | | All drill core processing was performed at the Relais Routier Km 381 Truck Stop, with logging and sampling conducted by employees and contractors of GLCI. Lithology, structure, mineralization, sample number, and location were recorded by the geologists in a GeoticLog log database, with a backup stored on an external hard drive for additional security.

Drill core was stored in wooden core boxes and delivered to the core logging facility at the camp twice daily by the drill contractor. The drill core was first aligned and measured for core recovery by a technician, followed by RQD measurements. Due to the hardness of the pegmatite units, the recovery of the drill core was generally very good, averaging over 95%. The core was then logged, and sampling intervals were defined by the geologist. Before sampling, the core was photographed using a digital camera and core boxes were marked with box number, hole ID, and aluminium tags indicating “from” and “to” measurements. All drill holes were logged in full. |

| Sub- sampling techniques and sample preparation | | If core, whether cut or sawn and whether quarter, half or all core taken.

If non-core, whether riffled, tube sampled, rotary split, etc. and whether sampled wet or dry.

For all sample types, the nature, quality and appropriateness of the sample preparation technique.

Quality control procedures adopted for all sub-sampling stages to maximise representivity of samples.

Measures taken to ensure that the sampling is representative of the in-situ material collected, including for instance results for field duplicate/second-half sampling.

Whether sample sizes are appropriate to the grain size of the material being sampled. | | 2008/2009 Drilling and Channel Sampling

Standardized core sampling protocols were used by Lithium One. Initially, during the 2008 drilling program, core was sampled at 2.5 m intervals, and subsequently at 1.5 m intervals. A selective sampling procedure was used based on lithological contacts, where the maximum (and most common) sample interval was 1.5 m. Shorter samples were collected to define geological domains. Channel samples were also sampled at 1.5 m intervals.

Sample intervals were marked by appropriately qualified geologists. Two sample tags were placed at the beginning of each sample interval, while a third copy remained in the sample booklet along with the associated “from” and “to” information recorded by the geologist.

A geo-technician was responsible for core cutting and for preparing the samples for dispatch to the preparation laboratory – Table Jamésienne de Concertation Minière in Chibougamau (TJCM). Assay samples were collected on half-core sawed lengthwise using a diamond saw; the remaining half was replaced in the core box for future reference. Quarter core duplicates were collected frequently.

2017/2018 Drilling

Sample intervals were determined based on observations of the lithology and mineralization and were marked and tagged by the geologist. The typical sample length was 1.5 m but varied according to lithological contacts between the mineralized pegmatite and the country rock. In general, one country rock sample was collected from each side of the contact with the pegmatite.

The drill core was split lengthwise; one half was placed in a plastic bag with a sample tag, and the other half was left in the core box with a second sample tag for reference. The third sample tag was archived on site. The samples were then catalogued and placed in rice bags for shipping. Sample shipment forms were prepared on site, with one copy inserted with the shipment and a second copy given to the carrier. One copy was kept for reference.

The samples were transported regularly by contractors’ truck directly to the ALS Canada Ltd – ALS Minerals laboratory in Val-d’Or, Québec. At the ALS facility, the sample shipment was verified, and a confirmation of receipt of shipment and content was sent digitally to the Galaxy project manager.

The sample sizes (half-core, NQ diameter) are appropriate for the style, thickness and consistency of the mineralization at the James Bay Lithium Project.

2021 – 2023 Drilling

Sampling techniques and preparation were consistent with the 2017/2018 drilling campaigns, with sampling lengths reduced to 1m within pegmatite lithologies. |

| Quality of assay data and laboratory tests | | The nature, quality and appropriateness of the assaying and laboratory procedures used and whether the technique is considered partial or total.

For geophysical tools, spectrometers, handheld XRF instruments, etc., the parameters used in determining the analysis including instrument make and model, reading times, calibrations factors applied and their derivation, etc.

Nature of quality control procedures adopted (e.g. standards, blanks, duplicates, external laboratory checks) and whether acceptable levels of accuracy (i.e. lack of bias) and precision have been established. | | 2008 - 2010 Assaying

Samples were shipped from site in secure containers to Table Jamésienne de Concertation Minière (TJCM) in Chibougamau for preparation. The protocol for sample preparation involved weighing, drying, crushing, splitting and pulverizing.

The pulverized pegmatite core samples were shipped from the TJCM to the COREM Research Laboratory (COREM) in Québec City. COREM was accredited ISO/IEC 17025:2005 by the Standards Council of Canada for various testing procedures on April 30, 2009. The scope of accreditation did not include the specific testing procedures used by COREM to assay lithium (method code B23).

Lithium One also utilized SGS Mineral Services Lakefield Laboratory (SGS) as an umpire laboratory to monitor the reliability of assaying results delivered by the primary laboratory COREM.

At COREM, prepared samples were assayed using three-acid digestion (nitric acid, hydrofluoric acid, perchloric acid) in boiling water. The dissolved sample was analysed by atomic absorption (AA) spectrometry. At SGS, check samples were assayed by sodium peroxide fusion and atomic absorption spectroscopy. At ALS Minerals, prepared samples were assayed using four-acid digestion (perchloric acid, hydrofluoric acid, nitric acid and hydrochloric acid) with ICP-AES finish. Although a four-acid digest is considered a near-total digest, common practice for the analysis of pegmatite material is a sodium-peroxide fusion. Significant verification test work has been undertaken and has demonstrated that the acid digest method is robust, and no bias has been observed when compared to the sodium-peroxide fusion check assays.

Samples from 2008 – 2010 represent roughly 14% of the total meterage of the drilling on the project.

2008 - 2010 QAQC

Lithium One relied partly on the internal analytical quality control measures implemented by COREM laboratory. Additionally, Lithium One implemented external analytical quality control measures consisting of using control samples (field blanks, in house standards and field duplicates) inserted with sample batches submitted for assaying in 2009 and 2010, and coarse reject duplicate samples in 2008. Standards were non-certified and were custom-made from a bulk sample of the outcropping pegmatite material from the project.

Field duplicates were generated from quarter core samples and inserted every 40 samples.

Total insertion rate for QAQC in 2008 – 2010 was 4.2%, with an additional 2.6% when including umpire assays.

Although the insertion rate of QAQC in 2008 – 2010 was below industry standards, subsequent check assays have shown that the assay results are valid. Also, the results from the limited QAQC undertaken at the time of drilling show no issues.

2017/2018 Assaying

Samples were shipped to ALS Minerals in Val-d’Or for preparation and analyses. The laboratory is accredited ISO/IEC 17025:2005 by the Standards Council of Canada for various testing procedures, however, the scope of accreditation does not include the specific testing procedure used to assay lithium.

Sample preparation involved the sample material being weighed and crushed to 70% passing 2 mm. The ground material was then pulverized to 90% passing 75 microns before being analysed.

At ALS Minerals, prepared samples were assayed for mineralization grade lithium by specialized four-acid digestion and inductively coupled plasma – atomic emission spectrometry (ICP-AES) finish (method code Li-OG63). An approximately 0.4-gr sample was first digested with perchloric, hydrofluoric, and nitric acid until dry. The residue was subsequently re-digested in concentrated hydrochloric acid, cooled and topped up to volume. Finally, the samples were analysed for lithium by ICP-AES. The method used has a lower detection limit of 0.005% lithium and an upper limit of 10% lithium.

Samples from 2017 represent roughly 44% of the total meterage of the drilling on the project.

2017/2018 QAQC

GLCI relied partly on the internal analytical quality control measures implemented by the ALS Minerals laboratory, which involved routine pulp duplicate analyses. GLCI also implemented external analytical quality control measures including the insertion of control samples (blanks, in house standards and field duplicates) with sample batches submitted for assaying at ALS Minerals in 2017. In 2017, a number of pulp samples were also re-submitted to the SGS laboratory in Lakefield, Ontario for umpire check assays. In 2020, additional pulp samples were resubmitted to Nagrom Analytical, Perth.

Duplicate samples were inserted into each sample series at a rate of one in every 20 samples. Duplicates corresponded to a quarter core from the sample left behind as reference.

Total insertion rate for QAQC in 2017 was 12.4%, with which increases up to 16.6% when including umpire assays.

The rate of insertion of QAQC samples in 2017 was much improved compared to 2008 – 2010 period. No biases were identified, and a minor failure was identified in the low-grade standard which was investigated and no issues were identified.

2021 - 2023 Assaying

Samples were shipped to ALS Minerals in Val-d’Or for preparation and analyses. The laboratory is accredited ISO/IEC 17025:2005 by the Standards Council of Canada for various testing procedures, however, the scope of accreditation does not include the specific testing procedure used to assay lithium.

Sample preparation (code PREP-31A) involved the sample material being weighed and crushed to 70% passing 2 mm, with a riffle split of 250g pulverized to 85% passing 75 microns before being analysed.

At ALS Minerals, prepared samples were assayed for mineralization-grade lithium by sodium-peroxide fusion and digestion followed by inductively coupled plasma – atomic emission spectrometry (ICP-AES) finish (method code ME-ICP81). The method used has a lower detection limit of 0.001% lithium and an upper limit of 10% lithium.

Samples from 2021 - 2023 represent roughly 42% of the total meterage of the drilling on the project.

2021 - 2023 QAQC

GLCI implemented external analytical quality control measures including the insertion of control samples (blanks and in house standards) with sample batches submitted for assaying at ALS Minerals at a rate of 1 QAQC sample for every 9 samples.

A number of pulp samples were also re-submitted to the SGS laboratory in Lakefield, Ontario for umpire check assays.

Total insertion rate for QAQC between 2021 and 2023 was roughly 12% when including umpire assays.

No biases were identified, and two minor blank failures were identified and a re-analysis was requested. The re-analyses returned similar results to the original assays.

|

| Verification of sampling and assaying | | The verification of significant intersections by either independent or alternative company personnel.

The use of twinned holes.

Documentation of primary data, data entry procedures, data verification, data storage (physical and electronic) protocols.

Discuss any adjustment to assay data. | | James Purchase, P. Geo, Geology Manager for Galaxy Lithium (Canada) Inc. has visually assessed and verified significant intersections of drill core described in this announcement and has witnessed outcropping spodumene mineralization in the field. A selection of drill collar coordinates was validated by handheld GPS, and core and sample storage and security facilities were inspected. Channel sample outcrops were also inspected and found to be of high-quality.

Numerous site visits have taken place since 2021, the most recent being in June 2023.

It should be noted that the drilling between 2021 and 2023 was managed by independent geological contractors and was conducted by professional geologists registered in the Province of Québec.

Data collection and entry procedures were also reviewed and found to be adequate. Various reanalyses of pulps have shown that there are very immaterial differences between analysing using a standard 4-acid digest and a peroxide fusion for the James Bay lithium deposit.

No clear and consistent biases were defined during investigations into QAQC performances, and any failures were duly investigated and found to be minor. |

| Location of data points | | Accuracy and quality of surveys used to locate drill holes (collar and down-hole surveys), trenches, mine workings and other locations used in Mineral Resource estimation.

Specification of the grid system used.

Quality and adequacy of topographic control. | | Drill collars were surveys by an external contractor using RTK methodology in UTM (Universal Transverse Mercator) Zone 18N. Datum is NAD83.

Downhole surveys were completed using an EZ-TRAC multishot tool provided by REFLEX. Declination (-14.2) was removed to correct the data from magnetic north to geographic north. At the collar, a TN14 tool was used to measure the dip and azimuth of the casing.

Topographic controls are informed by a LiDAR survey completed recently on the project. |

| Data Spacing and distribution | | Data spacing for reporting of Exploration Results.

Whether the data spacing and distribution is sufficient to establish the degree of geological and grade continuity appropriate for the Mineral Resource and Ore Reserve estimation procedure(s) and classifications applied.

Whether sample compositing has been applied. | | In the NW Sector, drilling has been completed on a nominal 80m x 80m spacing.

The remainder of the deposit has been drilled at a nominal spacing of between 40 and 50 metres to satisfy the classification of the deposit as Indicated Mineral Resources.

No sample compositing has been undertaken for the purposes of reporting exploration results. |

| Orientation of data in relation to geological structure | | Whether the orientation of sampling achieves unbiased sampling of possible structures and the extent to which this is known, considering the deposit type.

If the relationship between the drilling orientation and the orientation of key mineralised structures is considered to have introduced a sampling bias, this should be assessed and reported if material. | | As the pegmatite dykes in the NW Sector are concealed by 5 – 15m of glacial till, it was difficult to accurately orientate the drilling at a perpendicular angle to the pegmatites as limited information was available at the time. As drilling progressed, it become apparent that the drilling was intersecting the pegmatites at a sub-optimal angle, and that the true thickness of pegmatites in drilling represent between 60 – 80% of the apparent thickness (downhole thicknesses). Although this angle is sub-optimal, the author does not believe this has introduced a sampling bias.

The orientation of the dykes are well understood for the remainder of the deposit where outcrop is abundant, and drilling has been oriented perpendicular to the dyke contacts. |

| Sample Security | | The measures taken to ensure sample security. | | Drill core, sample rejects and sample pulps are stored in a secure environment (in a locked dome structure) at the Relai Routier 381 truck stop. Sample pulps are stored in a locked container adjacent to the dome. |

| Audits or reviews | | The results of any audits or reviews of sampling techniques and data | | Sampling techniques were reviewed by previous employees of Galaxy Lithium, and also by James Purchase, P.Geo, the QP of the previous Mineral Resource released in the 2021 feasibility study. In addition, external geological contractors were engaged during drilling activities to monitor the QAQC data and logging procedures to ensure that industry best practises were followed. |

Section 2: Reporting of Exploration Results

| Criteria | | JORC Code explanation | | Commentary |

| Mineral tenement and land tenure status | | - Type, reference name/number, location and ownership including agreements or material issues with third parties such as joint ventures, partnerships, overriding royalties, native title interests, historical sites, wilderness or national park and environmental settings.

- The security of the tenure held at the time of reporting along with any known impediments to obtaining a license to operate in the area.

| | The Project comprises 224 mining titles located primarily in NTS map sheet 33C/03, covering an area of approximately 11,130 hectares. The boundaries of the claims have not been legally surveyed. All claims are in good standing, with expiry dates between June 12, 2024, and November 2, 2025. The claims are “CDC”-type claims which gives its holder the exclusive right to search for mineral substances. No Mining Lease has been issued for the project. The claims are registered under Galaxy Lithium (Canada) Inc. (“GLCI”), Galaxy Lithium (Ontario) Inc. (“GLOI”) or Select Lithium Corp (claims currently being transferred to GLCI).

|

| Exploration done by other parties | | - Acknowledgment and appraisal of exploration by other parties.

| | Prospector Jean Cyr first discovered spodumene pegmatite outcrops on the property in 1964. The property was staked in 1966 by Mr. Cyr and was optioned by the SDBJ in 1974, who after conducting some exploration on the property, returned it to Mr. Cyr on June 10, 1986.

Commencing in 1974, SDBJ conducted an exploration program that consisted of geological mapping, systematic sampling and diamond drilling of the mineralized outcrops to evaluate the lithium potential of the property. The mapping defined an area of 45,000 square metres of outcropping spodumene dykes.

The Centre de Recherches Minérales du Québec conducted concentration tests and chemical analyses in 1975. A composite sample of the spodumene pegmatite grading 1.7% Li2O yielded a spodumene concentrate grading an average of 6.2% Li2O with a recovery factor of 71%.

LithiumOne acquired the claims in 2007 and embarked on an exploration campaign designed to produce a maiden mineral resource on the property. In 2012, Galaxy Resources Limited merged with Lithium One.

|

| Geology | | - Deposit type, geological setting and style of mineralization.

| | The Project is in the north-eastern part of the Superior Province. It lies within the Lower Eastmain Group of the Eastmain greenstone belt, which consists predominantly of amphibolite grade mafic to felsic metavolcanic rocks, metasedimentary rocks and minor gabbroic intrusions.

The property is underlain by the Auclair Formation, consisting mainly of paragneisses of probable sedimentary origin which surround the pegmatite dykes to the northwest and southeast. Volcanic rocks of the Komo Formation occur to the north of the pegmatite dykes. The greenstone rocks are surrounded by Mesozonal to catazonal migmatite and gneiss. All rock units are Archean in age.

The pegmatites delineated on the property to date are oriented in a generally parallel direction to each other and are separated by barren host rock of sedimentary origin (metamorphosed to amphibolite facies). They form irregular dykes attaining up to 60 m in width and over 200 m in length. The pegmatites crosscut the regional foliation at a high angle, striking to the south-southwest and dipping moderately to the west-northwest.

Spodumene is the principal source of lithium found at the Project. Spodumene is a relatively rare pyroxene that is composed of lithium (8.03% Li2O), aluminium (27.40% Al2O3), and silica (64.57% SiO2). It is found in lithium rich granitic pegmatites, with its occurrence associated with quartz, microcline, albite, muscovite, lepidolite, tourmaline and beryl.

|

| Drill hole Information | | - A summary of all information material to the understanding of the exploration results including a tabulation of the following information for all Material drill holes:

- easting and northing of the drill hole collar

- elevation or RL (Reduced Level – elevation above sea level in meters) of the drill hole collar

- dip and azimuth of the hole

- down hole length and interception depth

- hole length.

| | All drill collars and hole directions are presented in Appendix 2 and 3. Most holes are inclined 45 – 70 degrees towards the southeast. |

| Data aggregation methods | | - In reporting Exploration Results, weighting averaging techniques, maximum and/or minimum grade truncations (e.g. cutting of high grades) and cut-off grades are usually Material and should be stated.

- Where aggregate intercepts incorporate short lengths of high-grade results and longer lengths of low-grade results, the procedure used for such aggregation should be stated and some typical examples of such aggregations should be shown in detail.

- The assumptions used for any reporting of metal equivalent values should be clearly stated.

| | No capping has been applied for the purpose of reporting exploration results.

Lower cut-off used for reporting is 0.4% Li2O%; minimum 4m true width interval; maximum 2m of internal waste. Only samples logged as pegmatite have been reported.

No metal equivalent values are used.

Li% assays have been multiplied by 2.153 to transform them to Li2O%.

|

| Relationship between mineralization widths and intercept lengths | | - These relationships are particularly important in the reporting of Exploration Results.

- If the geometry of the mineralization with respect to the drill hole angle is known, its nature should be reported.

- If it is not known and only the down hole lengths are reported, there should be a clear statement to this effect (e.g. ‘down hole length, true width not known’).

| | Lithium mineralization in the NW Sector occurs as thick, steeply dipping pegmatite dykes ranging between 4 and 30 metres thick (true thickness), with some dykes coalescing up to 85m true thickness in the core of the pegmatite swarm.

Due to the sub-optimal angle of intercept between the drilling at the assumed orientation of the pegmatite dykes in the NW Sector, true widths have been estimated at between 60% and 80% of downhole widths.

|

| Diagrams | | - Appropriate maps and sections (with scales) and tabulations of intercepts should be included for any significant discovery being reported These should include, but not be limited to a plan view of drill hole collar locations and appropriate sectional views.

| | A map view has been provided.

|

| Balanced reporting | | - Where comprehensive reporting of all Exploration Results is not practicable, representative reporting of both low and high grades and/or widths should be practiced to avoid misleading reporting of Exploration Results.

| | All significant intersections above 0.4% Li2O with a minimum true width of 4m have been reported. A maximum internal waste of 2m has been allowed. |

| Other substantive exploration data | | - Other exploration data, if meaningful and material, should be reported including (but not limited to): geological observations; geophysical survey results; geochemical survey results; bulk sample– size and method of treatment; metallurgical test results; bulk density, groundwater, geotechnical and rock characteristics; potential deleterious or contaminating substances.

| | Bulk sampling was conducted on the property in 2011, a four test pits were dug to obtain metallurgical samples.

An IP survey undertaken in 2020 and 2021 has uncovered potential extensions of mineralization to the east of the property, east of the Billy-Diamond Highway.

Re-assaying of pulps using multi-element sodium-peroxide fusion methods has not returned economic concentrations of tantalum, tin or other elements of economic importance apart from Lithium. |

| Further work | | - The nature and scale of planned further work (e.g. tests for lateral extensions or depth extensions or large-scale step-out drilling).

- Diagrams clearly highlighting the areas of possible extensions, including the main geological interpretations and future drilling areas, provided this information is not commercially sensitive.

| | Downhole televiewer survey is planned to determine geometry of newly discovered pegmatites in the NW Sector. In addition, an aeromagnetic survey covering NW Sector has just been concluded and results should be available shortly.

Infill drilling at the NW Sector is planned, with additional step-out exploration drilling to identify additional pegmatite dykes. |

Appendix 2: All drillhole collars from the 2023 drilling program.

| Hole ID | TYPE | UTM 18N East | UTM 18N North | RL | Depth | Dip | UTM 18N Azimuth |

| JBL-22-093 | DDH | 359220 | 5789142 | 232 | 102 | -45 | 112 |

| JBL-22-094 | DDH | 359108 | 5789105 | 238 | 177 | -45 | 112 |

| JBL-22-095 | DDH | 358989 | 5789293 | 236 | 102 | -45 | 122 |

| JBL-22-096 | DDH | 359112 | 5789137 | 234 | 176.4 | -45 | 112 |

| JBL-22-097 | DDH | 358947 | 5789320 | 237 | 160 | -45 | 122 |

| JBL-22-098 | DDH | 359126 | 5789175 | 233 | 192.6 | -45 | 112 |

| JBL-22-099 | DDH | 358853 | 5789321 | 239 | 102 | -45 | 112 |

| JBL-22-100 | DDH | 358989 | 5788959 | 226 | 222 | -45 | 112 |

| JBL-22-101 | DDH | 358830 | 5789401 | 225 | 102 | -45 | 112 |

| JBL-22-102 | DDH | 359253 | 5789254 | 226 | 81 | -45 | 112 |

| JBL-22-103 | DDH | 358751 | 5789422 | 223 | 135 | -48 | 117 |

| JBL-22-104 | DDH | 359243 | 5789221 | 227 | 72 | -43 | 112 |

| JBL-22-105 | DDH | 359190 | 5789243 | 227 | 126.25 | -43 | 112 |

| JBL-22-106 | DDH | 358811 | 5789349 | 231 | 126 | -45 | 112 |

| JBL-22-107 | DDH | 359133 | 5789217 | 230 | 177 | -43 | 112 |

| JBL-22-108 | DDH | 358655 | 5789416 | 221 | 177 | -60 | 112 |

| JBL-22-109 | DDH | 358701 | 5789155 | 233 | 249 | -44 | 117 |

| JBL-22-110 | DDH | 358971 | 5789127 | 243 | 300.1 | -45 | 112 |

| JBL-22-111 | DDH | 358360 | 5789520 | 219 | 201 | -45 | 112 |

| JBL-22-112 | DDH | 358804 | 5789076 | 229 | 282 | -45 | 122 |

| JBL-22-113 | DDH | 358029 | 5789407 | 225 | 90 | -45 | 122 |

| JBL-22-114 | DDH | 357977 | 5789423 | 226 | 147.1 | -45 | 122 |

| JBL-22-115 | DDH | 358997 | 5789082 | 239 | 276 | -55 | 112 |

| JBL-22-116 | DDH | 358067 | 5789750 | 214 | 87 | -45 | 112 |

| JBL-22-116A | DDH | 358069 | 5789754 | 214 | 18 | -45 | 112 |

| JBL-22-117 | DDH | 358759 | 5789179 | 240 | 201 | -45 | 112 |

| JBL-22-118 | DDH | 358042 | 5789706 | 215 | 102 | -45 | 112 |

| JBL-22-119 | DDH | 358971 | 5789180 | 245 | 300 | -45 | 112 |

| JBL-22-120 | DDH | 358045 | 5789835 | 213 | 177 | -45 | 112 |

| JBL-23-001 | DDH | 359008 | 5789224 | 240 | 285 | -43 | 112 |

| JBL-23-002 | DDH | 357657 | 5789785 | 214 | 510 | -45 | 142 |

| JBL-23-003 | DDH | 357495 | 5789831 | 213 | 336 | -45 | 162 |

| JBL-23-004 | DDH | 359027 | 5789258 | 236 | 279 | -43 | 112 |

| JBL-23-005 | DDH | 357428 | 5789816 | 213 | 201 | -45 | 162 |

| JBL-23-006 | DDH | 357391 | 5789801 | 214 | 219 | -45 | 162 |

| JBL-23-007 | DDH | 357723 | 5789788 | 213 | 111 | -50 | 142 |

| JBL-23-008 | DDH | 359144 | 5789527 | 224 | 102 | -45 | 112 |

| JBL-23-009 | DDH | 357717 | 5789834 | 214 | 252 | -41 | 152 |

| JBL-23-010 | DDH | 357201 | 5790265 | 207 | 250 | -45 | 152 |

| JBL-23-011 | DDH | 357294 | 5789806 | 213 | 111 | -47 | 147 |

| JBL-23-012 | DDH | 357262 | 5789862 | 211 | 132 | -44 | 152 |

| JBL-23-013 | DDH | 357691 | 5789865 | 213 | 129 | -50 | 142 |

| JBL-23-013A | DDH | 357689 | 5789870 | 213 | 21 | -50 | 142 |

| JBL-23-014 | DDH | 357227 | 5789866 | 210 | 159 | -45 | 152 |

| JBL-23-015 | DDH | 357652 | 5789853 | 213 | 327 | -50 | 142 |

| JBL-23-016 | DDH | 357197 | 5789840 | 210 | 135 | -45 | 152 |

| JBL-23-017 | DDH | 357218 | 5789798 | 213 | 102 | -45 | 152 |

| JBL-23-018 | DDH | 357134 | 5789833 | 210 | 195 | -44 | 161 |

| JBL-23-019 | DDH | 357132 | 5790224 | 207 | 250 | -45 | 152 |

| JBL-23-020 | DDH | 357112 | 5789881 | 210 | 150 | -45 | 161 |

| JBL-23-021 | DDH | 357660 | 5789904 | 212 | 147 | -50 | 142 |

| JBL-23-022 | DDH | 357623 | 5789887 | 212 | 156.3 | -50 | 142 |

| JBL-23-023 | DDH | 357071 | 5789880 | 210 | 150 | -45 | 162 |

| JBL-23-024 | DDH | 357285 | 5790125 | 208 | 282 | -45 | 152 |

| JBL-23-025 | DDH | 357574 | 5789891 | 212 | 207 | -55 | 142 |

| JBL-23-026 | DDH | 357033 | 5789870 | 210 | 150 | -44 | 162 |

| JBL-23-027 | DDH | 357454 | 5789950 | 210 | 294.5 | -55 | 162 |

| JBL-23-028 | DDH | 356989 | 5789857 | 210 | 150 | -45 | 162 |

| JBL-23-029 | DDH | 357010 | 5789809 | 210 | 105 | -45 | 162 |

| JBL-23-030 | DDH | 357532 | 5789972 | 210 | 300 | -45 | 162 |

| JBL-23-031 | DDH | 357214 | 5790084 | 208 | 325 | -45 | 152 |

| JBL-23-032 | DDH | 357558 | 5789652 | 214 | 300 | -45 | 142 |

| JBL-23-033 | DDH | 357531 | 5789973 | 210 | 252 | -70 | 152 |

| JBL-23-034 | DDH | 357592 | 5789677 | 214 | 351 | -45 | 142 |

| JBL-23-035 | DDH | 357505 | 5789905 | 211 | 363.3 | -45 | 162 |

| JBL-23-036 | DDH | 357695 | 5789650 | 214 | 402 | -47 | 142 |

| JBL-23-036A | DDH | 357696 | 5789651 | 214 | 24 | -47 | 142 |

| JBL-23-037 | DDH | 357529 | 5789850 | 213 | 325.7 | -45 | 162 |

| JBL-23-038 | DDH | 357471 | 5789896 | 211 | 351 | -50 | 162 |

| JBL-23-039 | DDH | 357278 | 5790019 | 210 | 252 | -50 | 152 |

| JBL-23-040 | DDH | 357129 | 5790394 | 208 | 300 | -45 | 142 |

| JBL-23-041 | DDH | 357356 | 5789989 | 210 | 171 | -46 | 164 |

| JBL-23-042 | DDH | 357151 | 5790434 | 208 | 318 | -45 | 142 |

| JBL-23-043 | DDH | 357516 | 5789880 | 211 | 714 | -48 | 152 |

| JBL-23-044 | DDH | 357308 | 5789944 | 211 | 87 | -47 | 164 |

| JBL-23-045 | DDH | 357357 | 5790164 | 208 | 252 | -45 | 152 |

| JBL-23-045A | DDH | 357354 | 5790167 | 208 | 23.6 | -45 | 152 |

| JBL-23-046 | DDH | 357103 | 5790489 | 208 | 336 | -45 | 142 |

| JBL-23-047 | DDH | 357270 | 5790305 | 207 | 300 | -45 | 152 |

| JBL-23-048 | DDH | 357037 | 5790443 | 208 | 312 | -45 | 142 |

| JBL-23-049 | DDH | 357146 | 5790043 | 208 | 321 | -45 | 152 |

| JBL-23-050 | DDH | 356988 | 5790501 | 208 | 300 | -45 | 142 |

| JBL-23-051 | DDH | 357070 | 5790362 | 208 | 261 | -45 | 142 |

| JBL-23-052 | DDH | 357316 | 5790227 | 207 | 303 | -45 | 152 |

| JBL-23-053 | DDH | 357061 | 5790583 | 207 | 300 | -45 | 142 |

| JBL-23-054 | DDH | 357248 | 5790189 | 208 | 312 | -45 | 152 |

| JBL-23-055 | DDH | 357645 | 5790028 | 209 | 150 | -45 | 142 |

| JBL-23-056 | DDH | 357403 | 5790088 | 209 | 300 | -45 | 152 |

| JBL-23-057 | DDH | 356978 | 5790573 | 207 | 402 | -46 | 142 |

| JBL-23-058 | DDH | 357803 | 5790037 | 208 | 102 | -45 | 142 |

| JBL-23-059 | DDH | 357993 | 5789453 | 224 | 141 | -45 | 127 |

| JBL-23-060 | DDH | 357958 | 5789395 | 225 | 51 | -45 | 122 |

| JBL-23-061 | DDH | 358032 | 5789495 | 223 | 450 | -45 | 112 |

| JBL-23-062 | DDH | 357331 | 5790057 | 209 | 276 | -45 | 152 |

| JBL-23-063 | DDH | 356936 | 5790459 | 209 | 300 | -45 | 142 |

| JBL-23-064 | DDH | 357201 | 5789983 | 210 | 276 | -50 | 152 |

| JBL-23-065 | DDH | 356982 | 5790405 | 209 | 306 | -45 | 142 |

| JBL-23-067 | DDH | 357214 | 5790466 | 208 | 300 | -44 | 141 |

| JBL-23-069 | DDH | 357161 | 5790528 | 207 | 315 | -45 | 142 |

| JBL-23-072 | DDH | 357107 | 5790298 | 208 | 312 | -45 | 147 |

| JBL-23-073 | DDH | 357178 | 5790150 | 207 | 150 | -45 | 155 |

| JBL-23-074 | DDH | 357111 | 5790596 | 207 | 315.3 | -45 | 142 |

| JBL-23-075 | DDH | 357190 | 5790208 | 206 | 201 | -45 | 155 |

| JBL-23-076 | DDH | 357019 | 5790341 | 209 | 300 | -45 | 147 |

| JBL-23-077 | DDH | 357264 | 5790243 | 207 | 312 | -47 | 152 |

| JBL-23-078 | DDH | 357057 | 5790660 | 206 | 300 | -45 | 142 |

| JBL-23-079 | DDH | 357008 | 5790424 | 209 | 300 | -45 | 147 |

| JBL-23-080 | DDH | 357214 | 5790394 | 208 | 300 | -47 | 147 |

| JBL-23-081 | DDH | 356937 | 5790510 | 208 | 357 | -47 | 147 |

| JBL-23-082 | DDH | 357013 | 5790618 | 207 | 372 | -45 | 142 |

| JBL-23-083 | DDH | 357317 | 5790141 | 208 | 201 | -45 | 152 |

| JBL-23-084 | DDH | 357354 | 5790166 | 208 | 150 | -45 | 107 |

| JBL-23-085 | DDH | 356988 | 5790407 | 209 | 330 | -45 | 105 |

| JBL-23-085A | DDH | 356988 | 5790407 | 209 | 44.15 | -45 | 107 |

| JBL-23-086 | DDH | 357298 | 5790354 | 207 | 150.35 | -45 | 107 |

| JBL-23-087 | DDH | 358458 | 5789341 | 231 | 552 | -55 | 112 |

| JBL-23-088 | DDH | 357035 | 5790275 | 209 | 177 | -45 | 107 |

| JBL-23-089 | DDH | 357391 | 5789925 | 209 | 327 | -48 | 150 |

| JBL-23-089A | DDH | 357391 | 5789923 | 209 | 24.9 | -48 | 152 |

| JBL-23-090 | DDH | 358801 | 5789116 | 237 | 552 | -55 | 111 |

| JBL-23-091 | DDH | 359663 | 5788941 | 217 | 156 | -45 | 112 |

| JBL-23-092 | DDH | 359447 | 5789097 | 231 | 147 | -45 | 112 |

| JBL-23-093 | DDH | 359493 | 5789213 | 227 | 149.65 | -45 | 112 |

| JBS-23-066 | DDH | 356201 | 5790286 | 211 | 126 | -50 | 142 |

| JBS-23-068 | DDH | 356200 | 5790141 | 215 | 126 | -50 | 142 |

| JBS-23-070 | DDH | 356298 | 5789990 | 211 | 126 | -50 | 142 |

| JBS-23-071 | DDH | 356104 | 5789936 | 211 | 126 | -50 | 142 |

Appendix 3: New Significant Assay Results since announcement on May 4th, 2023.

Notes: Lower reporting cut-off 0.4% Li2O%; minimum 4m true thickness interval; maximum 2m of internal waste. Assay results are only reported within logged pegmatite intervals. Estimated true thicknesses are calculated from the intersection of the downhole surveys with three separate planes, depending on location, representing the geometry of the pegmatite dykes.

| Drillhole | From (m) | To (m) | Downhole Thickness (m) | Estimated True Thickness (m) | Li20% |

JBL-22-094

| 23.5 | 28.5 | 5.0 | 4.9 | 1.76 |

| 64.0 | 68.8 | 4.8 | 4.8 | 1.12 |

| 125.1 | 137.6 | 12.5 | 12.3 | 1.30 |

| 139.6 | 145.1 | 5.5 | 5.5 | 1.45 |

| JBL-22-095 | 74.7 | 78.8 | 4.1 | 4.1 | 1.28 |

JBL-22-096

| 60.3 | 65.3 | 5.0 | 5.0 | 1.04 |

| 114.6 | 123.7 | 9.1 | 9.0 | 1.14 |

| 136.3 | 141.1 | 4.8 | 4.7 | 2.01 |

| JBL-22-097 | 111.7 | 116.5 | 4.8 | 4.7 | 1.35 |

| JBL-22-098 | 122.4 | 134.4 | 12.0 | 11.8 | 1.58 |

| JBL-22-099 | 7.3 | 11.6 | 4.4 | 4.3 | 1.11 |

| JBL-22-100 | 176.1 | 184.1 | 8.0 | 8.0 | 1.16 |

| JBL-22-102 | 49.3 | 60.3 | 11.0 | 10.9 | 1.14 |

JBL-22-103

| 3.6 | 8.0 | 4.4 | 4.3 | 0.84 |

| 52.1 | 68.3 | 16.2 | 16.0 | 1.10 |

| JBL-22-105 | 98.0 | 104.3 | 6.3 | 6.3 | 0.77 |

JBL-22-106

| 20.6 | 30.3 | 9.7 | 9.6 | 1.64 |

| 71.1 | 75.8 | 4.7 | 4.6 | 1.06 |

| JBL-22-107 | 135.0 | 144.0 | 9.0 | 8.9 | 1.08 |

JBL-22-108

| 114.5 | 119.2 | 4.7 | 4.4 | 0.82 |

| 133.3 | 144.0 | 10.8 | 10.0 | 1.12 |

JBL-22-109

| 83.8 | 101.6 | 17.8 | 17.4 | 1.38 |

| 118.0 | 125.9 | 7.9 | 7.7 | 1.97 |

| 133.3 | 144.6 | 11.3 | 11.1 | 2.10 |

JBL-22-110

| 172.1 | 176.2 | 4.1 | 4.1 | 1.40 |

| 246.0 | 252.3 | 6.3 | 6.2 | 1.06 |

| JBL-22-112 | 268.0 | 274.2 | 6.1 | 5.8 | 0.57 |

| JBL-22-114 | 43.0 | 47.9 | 4.9 | 4.8 | 0.97 |

JBL-22-115

| 39.3 | 44.7 | 5.4 | 5.2 | 1.69 |

| 63.3 | 69.0 | 5.7 | 5.4 | 1.42 |

| 206.1 | 212.1 | 6.0 | 5.7 | 1.29 |

| 221.2 | 238.1 | 17.0 | 16.2 | 1.48 |

JBL-22-117

| 7.0 | 11.7 | 4.7 | 4.6 | 1.23 |

| 16.1 | 26.5 | 10.4 | 10.2 | 1.59 |

| 64.0 | 70.8 | 6.8 | 6.7 | 1.48 |

| 79.5 | 85.2 | 5.8 | 5.7 | 1.32 |

| 88.0 | 96.4 | 8.5 | 8.3 | 1.52 |

| 102.9 | 107.9 | 5.1 | 5.0 | 1.79 |

| 156.6 | 163.9 | 7.3 | 7.1 | 1.48 |

JBL-22-119

| 9.8 | 14.9 | 5.1 | 5.1 | 1.08 |

| 103.0 | 107.6 | 4.6 | 4.6 | 1.23 |

| 257.5 | 263.5 | 6.0 | 5.9 | 1.29 |

| 278.2 | 285.0 | 6.8 | 6.7 | 1.21 |

| JBL-23-001 | 222.5 | 228.2 | 5.7 | 5.6 | 1.38 |

JBL-23-002

| 9.1 | 13.6 | 4.5 | 4.1 | 0.88 |

| 42.0 | 124.0 | 82.0 | 74.7 | 1.52 |

| 239.2 | 253.5 | 14.3 | 12.7 | 1.38 |

| 267.7 | 305.9 | 38.2 | 33.6 | 1.42 |

| 351.0 | 374.8 | 23.8 | 20.6 | 1.24 |

| 381.0 | 394.6 | 13.7 | 11.8 | 1.41 |

| 397.7 | 405.8 | 8.1 | 7.0 | 1.71 |

| 426.8 | 434.2 | 7.4 | 6.3 | 1.22 |

| 452.3 | 471.6 | 19.3 | 16.3 | 1.46 |

JBL-23-003

| 113.0 | 149.7 | 36.7 | 28.5 | 1.54 |

| 229.8 | 235.7 | 5.9 | 4.5 | 1.32 |

| 242.8 | 267.6 | 24.8 | 19.0 | 1.17 |

JBL-23-004

| 36.4 | 42.8 | 6.4 | 6.3 | 0.93 |

| 231.3 | 235.4 | 4.2 | 4.1 | 0.77 |

| JBL-23-009 | 27.5 | 40.9 | 13.4 | 11.5 | 1.26 |

| JBL-23-011 | 33.2 | 45.0 | 11.8 | 10.2 | 1.54 |

JBL-23-012

| 6.0 | 12.0 | 6.0 | 5.1 | 1.25 |

| 30.0 | 53.0 | 23.0 | 19.7 | 1.29 |

| 108.2 | 115.2 | 7.0 | 5.9 | 1.71 |

JBL-23-013

| 21.0 | 33.9 | 12.9 | 11.7 | 1.93 |

| 64.2 | 68.7 | 4.5 | 4.1 | 1.40 |

| 72.3 | 79.9 | 7.6 | 6.8 | 1.26 |

JBL-23-014

| 26.0 | 37.0 | 11.0 | 9.3 | 1.51 |

| 131.0 | 136.4 | 5.5 | 4.5 | 0.95 |

JBL-23-015

| 5.5 | 10.0 | 4.6 | 4.1 | 1.60 |

| 53.2 | 65.5 | 12.3 | 11.1 | 1.47 |

| 92.1 | 105.9 | 13.9 | 12.5 | 1.63 |

| 270.7 | 280.4 | 9.8 | 8.5 | 1.60 |

JBL-23-016

| 16.7 | 27.4 | 10.8 | 9.1 | 1.35 |

| 104.1 | 120.0 | 15.9 | 13.3 | 1.83 |

| JBL-23-017 | 51.4 | 76.4 | 25.0 | 20.9 | 1.82 |

| JBL-23-018 | 137.2 | 144.2 | 7.0 | 5.3 | 1.50 |

| JBL-23-020 | 33.0 | 43.0 | 10.0 | 7.8 | 1.60 |

JBL-23-021

| 42.8 | 56.5 | 13.8 | 12.5 | 1.62 |

| 109.2 | 120.0 | 10.8 | 9.7 | 1.13 |

JBL-23-022

| 21.5 | 28.7 | 7.2 | 6.6 | 1.25 |

| 42.1 | 48.0 | 6.0 | 5.4 | 1.82 |

| 60.0 | 65.0 | 5.0 | 4.5 | 0.86 |

| 84.9 | 99.7 | 14.9 | 13.4 | 1.19 |

| 135.0 | 144.9 | 9.8 | 8.9 | 1.35 |

| JBL-23-023 | 61.2 | 72.0 | 10.8 | 8.3 | 1.02 |

JBL-23-025

| 2.9 | 19.1 | 16.2 | 14.4 | 1.62 |

| 77.9 | 90.8 | 12.9 | 11.4 | 1.95 |

| 145.9 | 151.1 | 5.2 | 4.6 | 1.19 |

| 185.0 | 195.9 | 10.9 | 9.6 | 1.51 |

| JBL-23-026 | 93.0 | 110.0 | 17.0 | 13.0 | 1.67 |

JBL-23-027

| 130.9 | 146.9 | 16.0 | 12.7 | 1.80 |

| 171.5 | 185.3 | 13.8 | 10.9 | 1.17 |

| 217.6 | 223.5 | 5.9 | 4.6 | 0.74 |

| 240.8 | 249.7 | 8.9 | 7.0 | 0.71 |

| 257.4 | 264.5 | 7.1 | 5.5 | 1.12 |

JBL-23-030

| 102.0 | 116.1 | 14.1 | 11.1 | 1.80 |

| 160.8 | 166.1 | 5.3 | 4.1 | 1.60 |

| 237.7 | 244.7 | 7.0 | 5.4 | 1.24 |

JBL-23-033

| 14.8 | 19.9 | 5.1 | 4.0 | 1.39 |

| 109.5 | 125.3 | 15.8 | 12.5 | 1.54 |

JBL-23-034

| 72.0 | 90.0 | 18.0 | 16.1 | 1.79 |

| 173.0 | 183.0 | 10.0 | 8.7 | 1.59 |

JBL-23-035

| 27.2 | 36.0 | 8.9 | 6.8 | 0.77 |

| 135.3 | 141.3 | 6.1 | 4.5 | 1.83 |

| 201.3 | 226.3 | 25.0 | 18.5 | 1.54 |

| 296.0 | 317.9 | 21.9 | 15.9 | 1.70 |

| 324.0 | 332.7 | 8.7 | 6.3 | 0.85 |

| 338.5 | 351.0 | 12.5 | 9.0 | 1.14 |

JBL-23-036

| 15.0 | 38.0 | 23.0 | 21.0 | 1.81 |

| 145.0 | 161.0 | 16.0 | 14.3 | 1.78 |

| 191.0 | 224.0 | 33.0 | 29.3 | 1.35 |

| 247.0 | 259.2 | 12.2 | 10.7 | 1.69 |

| JBL-23-036A | 15.0 | 24.0 | 9.0 | 8.1 | 1.92 |

JBL-23-037

| 131.6 | 155.6 | 24.0 | 18.4 | 1.50 |

| 240.0 | 259.9 | 19.9 | 14.8 | 1.74 |

| 272.7 | 278.5 | 5.8 | 4.3 | 1.37 |

| 282.5 | 307.0 | 24.5 | 18.1 | 1.46 |

| JBL-23-038 | 215.0 | 235.8 | 20.8 | 15.4 | 1.56 |

JBL-23-041

| 60.0 | 72.5 | 12.5 | 9.5 | 2.40 |

| 127.0 | 134.0 | 7.0 | 5.3 | 1.49 |

| 139.8 | 145.4 | 5.7 | 4.3 | 1.89 |

JBL-23-043

| 180.0 | 186.0 | 6.0 | 5.0 | 1.87 |

| 198.4 | 206.0 | 7.6 | 6.4 | 1.16 |

| 294.7 | 305.4 | 10.8 | 8.9 | 1.81 |

| 311.5 | 345.2 | 33.7 | 27.8 | 1.72 |

JBL-23-043

| 438.0 | 480.5 | 42.5 | 34.4 | 1.48 |

| 522.4 | 528.0 | 5.6 | 4.4 | 0.55 |

| JBL-23-044 | 22.8 | 52.1 | 29.3 | 22.6 | 1.48 |

| JBL-23-047 | 251.2 | 256.1 | 4.9 | 4.3 | 1.69 |

JBL-23-049

| 229.8 | 237.1 | 7.3 | 5.4 | 1.45 |

| 243.4 | 266.0 | 22.6 | 16.6 | 1.68 |

JBL-23-050

| 140.5 | 254.8 | 114.3 | 79.8 | 1.73 |

| 264.0 | 275.0 | 11.0 | 7.4 | 1.69 |

| JBL-23-051 | 91.0 | 108.0 | 17.0 | 11.6 | 1.37 |

| JBL-23-053 | 86.0 | 100.0 | 14.1 | 9.9 | 1.60 |

JBL-23-054

| 52.7 | 107.7 | 55.0 | 48.2 | 1.84 |

| 168.7 | 174.7 | 6.0 | 5.3 | 1.32 |

| JBL-23-055 | 47.8 | 54.5 | 6.7 | 6.1 | 1.68 |

JBL-23-059

| 64.0 | 69.0 | 5.0 | 4.8 | 0.85 |

| 76.9 | 100.8 | 23.9 | 23.1 | 1.63 |

JBL-23-061

| 10.0 | 24.7 | 14.7 | 14.4 | 1.85 |

| 43.1 | 49.1 | 6.1 | 5.9 | 1.39 |

| 58.0 | 71.1 | 13.1 | 12.8 | 1.47 |

| 84.2 | 102.1 | 18.0 | 17.7 | 2.02 |

| 145.7 | 150.9 | 5.2 | 5.1 | 1.41 |

| 279.4 | 287.0 | 7.6 | 7.5 | 0.68 |

| 358.5 | 366.5 | 8.0 | 7.8 | 1.17 |

JBL-23-064

| 181.5 | 205.7 | 24.2 | 19.5 | 1.70 |

| 225.0 | 233.0 | 8.0 | 6.4 | 1.43 |

JBL-23-065

| 191.0 | 221.0 | 30.0 | 19.7 | 1.94 |

| 276.0 | 296.0 | 20.0 | 13.1 | 2.80 |

JBL-23-072

| 66.0 | 91.9 | 25.9 | 15.9 | 1.64 |

| 295.0 | 303.0 | 8.0 | 4.7 | 0.77 |

JBL-23-074

| 29.4 | 39.3 | 9.9 | 6.6 | 1.74 |

| 258.4 | 271.1 | 12.7 | 8.4 | 1.48 |

| 280.5 | 299.7 | 19.2 | 12.7 | 1.70 |

| JBL-23-076 | 131.0 | 167.0 | 36.0 | 22.3 | 1.83 |

JBL-23-077

| 58.0 | 84.6 | 26.6 | 23.4 | 1.89 |

| 214.9 | 242.4 | 27.6 | 24.5 | 1.48 |

| 297.9 | 304.3 | 6.4 | 5.7 | 1.90 |

JBL-23-080

| 45.0 | 65.0 | 20.0 | 13.3 | 1.59 |

| 120.8 | 129.3 | 8.5 | 5.7 | 1.83 |

JBL-23-081

| 30.0 | 43.7 | 13.7 | 8.8 | 1.70 |

| 45.6 | 55.0 | 9.4 | 6.0 | 2.12 |

| 233.0 | 255.0 | 22.0 | 14.2 | 1.55 |

| 292.3 | 338.7 | 46.4 | 29.6 | 1.80 |

JBL-23-082

| 127.0 | 138.4 | 11.4 | 7.7 | 1.32 |

| 153.4 | 163.9 | 10.5 | 7.1 | 2.11 |

| 166.2 | 172.5 | 6.3 | 4.3 | 1.56 |

| 178.0 | 217.5 | 39.5 | 26.4 | 1.67 |

| 228.5 | 260.8 | 32.3 | 21.5 | 1.53 |

| 264.2 | 281.7 | 17.5 | 11.6 | 1.39 |

| 289.4 | 369.1 | 79.7 | 52.1 | 1.64 |

JBL-23-083

| 108.7 | 152.4 | 43.8 | 38.4 | 1.77 |

| 154.9 | 161.0 | 6.2 | 5.4 | 1.02 |

| JBL-23-084 | 76.5 | 95.3 | 18.8 | 18.2 | 1.77 |

JBL-23-085

| 107.0 | 201.1 | 94.1 | 84.5 | 1.87 |

| 207.8 | 214.6 | 6.8 | 6.2 | 1.76 |

| 230.9 | 243.4 | 12.5 | 11.2 | 1.52 |

| 252.8 | 264.4 | 11.7 | 10.5 | 1.83 |

| 274.1 | 278.9 | 4.8 | 4.3 | 2.03 |

| 281.1 | 285.8 | 4.8 | 4.3 | 1.27 |

| 321.0 | 325.8 | 4.8 | 4.3 | 1.59 |

JBL-23-087

| 68.7 | 75.0 | 6.3 | 6.1 | 0.82 |

| 88.8 | 96.5 | 7.7 | 7.3 | 1.12 |

| 110.2 | 118.8 | 8.6 | 8.2 | 1.64 |

| 185.2 | 195.7 | 10.5 | 9.9 | 1.20 |

| 216.0 | 222.2 | 6.2 | 5.9 | 1.91 |

JBL-23-089

| 49.2 | 61.8 | 12.6 | 10.8 | 1.65 |

| 272.0 | 279.0 | 7.0 | 5.8 | 1.12 |

| 285.0 | 294.0 | 9.0 | 7.4 | 0.71 |

JBL-23-090

| 17.0 | 27.9 | 10.9 | 10.3 | 1.57 |

| 38.7 | 54.4 | 15.7 | 14.9 | 1.61 |

| 55.7 | 76.8 | 21.1 | 20.1 | 1.93 |

| 195.2 | 200.9 | 5.7 | 5.4 | 1.40 |

| 250.0 | 254.9 | 4.9 | 4.7 | 1.72 |

| JBL-23-092 | 59.1 | 64.1 | 5.0 | 4.9 | 1.02 |

Notes: Lower reporting cut-off 0.4% Li2O% based on geological and geometallurgical parameters; minimum 4m true thickness interval; maximum 2m of internal waste. Assay results are only reported within logged pegmatite intervals. Estimated true thicknesses are calculated from the intersection of the downhole surveys with three separate planes, depending on location, representing the geometry of the pegmatite dykes.

Photos accompanying this announcement are available at

https://www.globenewswire.com/NewsRoom/AttachmentNg/367687c8-2804-489b-b83c-745631c13183https://www.globenewswire.com/NewsRoom/AttachmentNg/35db22b4-5daf-4757-88e4-c18a2c4f3331

Figure 1

James Bay 2023 drilling program – Plan view of drill collars

Figure 2

NW Sector cross section, looking north-east.

© 2026 Canjex Publishing Ltd. All rights reserved.