MONTREAL, Feb. 12, 2026 (GLOBE NEWSWIRE) -- HPQ Silicon Inc. (“HPQ” or the “Company”) (“HPQ” or the “Company”) (TSX-V: HPQ, OTCQB: HPQFF, FRA: O08), a technology company driving innovation in advanced materials and critical process development, announced that its wholly owned subsidiary, HPQ Silica Polvere Inc. (“HSPI”) [1], has signed a non-binding memorandum of understanding (the “MOU”) with a strategic industrial partner to advance the construction and operation of a commercial-scale fumed silica production plant.

The proposed project anticipates the formation of a jointly owned operating company that would build and operate a 1,000-tonne-per-year commercial fumed silica facility with an estimated total project value of US$20.0 million (approximately C$27.3 million). The plant would be designed and built by PyroGenesis Inc., using HSPI proprietary plasma-based Fumed Silica Reactor (“FSR”) technology. The strategic partner, whose identity is being withheld for confidentiality and competitive reasons, has already secured project financing and would fund the construction of the facility.

“The project and joint venture under consideration are supported by secured financing and an industrial partner with defined market requirements. While this remains subject to technical validation and final agreements, it reflects tangible market interest in deploying our technology at scale,” said Bernard Tourillon, President and CEO of HPQ Silicon and HPQ Silica Polvere Inc..

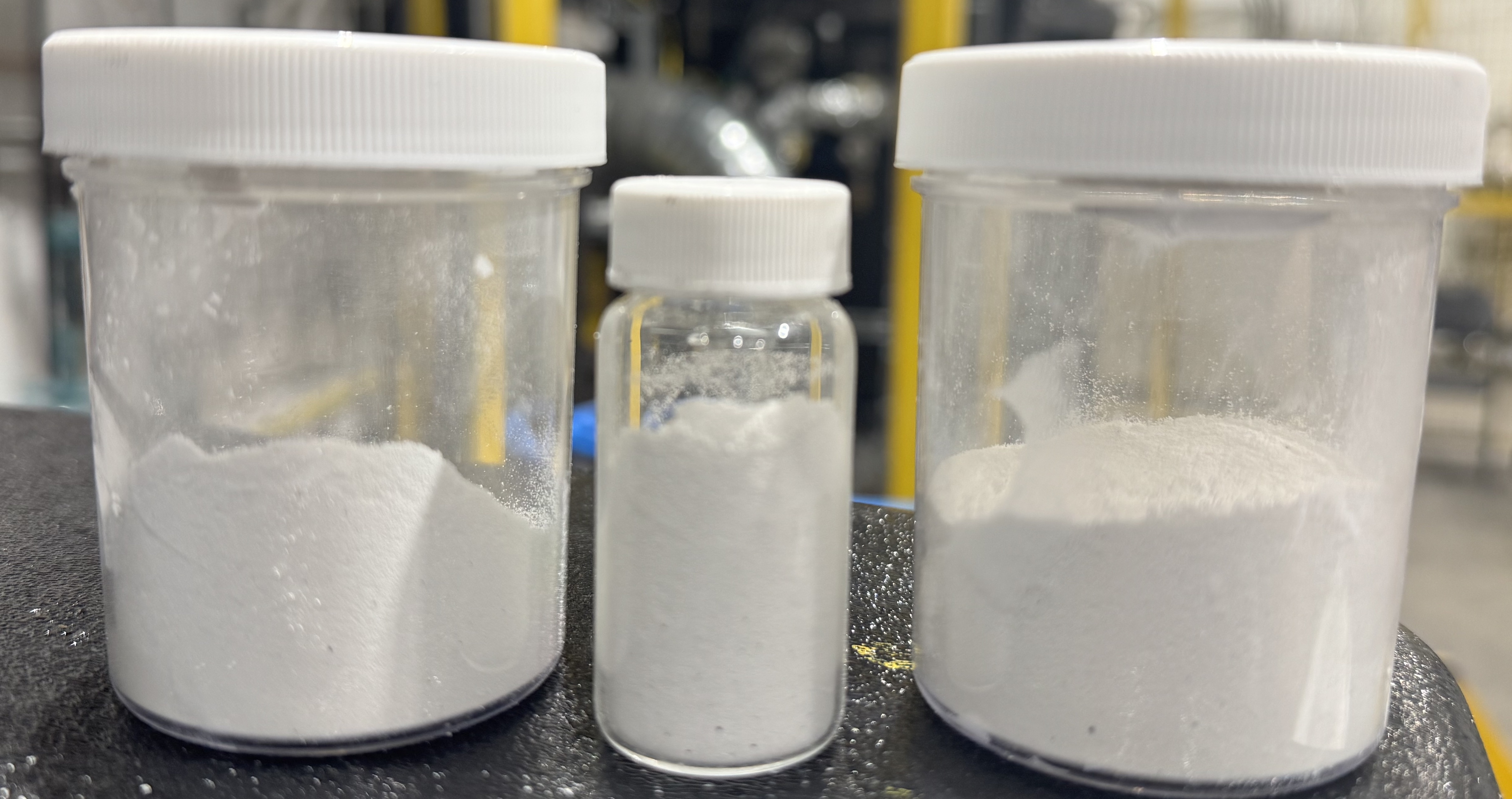

Image: fumed silica, produced by the fumed silica reactor.

Commercial Structure and Strategic Intent

The joint venture is expected to own and operate the facility, with production sold under an offtake arrangement to the strategic partner (terms and conditions yet to be agreed upon). Under the contemplated structure, HSPI would receive recurring royalties on each kilogram of fumed silica sold, (price/kg not yet agreed upon), providing HSPI and HPQ with long-term exposure to operating revenues while maintaining a capital-efficient profile.

This structure is intended to align HSPI and HPQ’s interests with long-term production performance while creating a platform that can be replicated across multiple sites as demand grows. Management views this approach as a scalable pathway to commercial deployment rather than a single, stand-alone facility.

Technical Validation and Path to Definitive Agreements

Progress toward final agreements remains contingent on the completion of ongoing third-party testing and validation of fumed silica produced by HSPI’s existing FSR pilot plant. Production samples have already been delivered to both the strategic partner and an independent specialty testing laboratory in the United States. These tests are focused on confirming chemical and compositional characteristics required for targeted commercial applications.

Subject to successful validation, the parties expect to complete the negotiation and execution of definitive joint venture and related agreements by the end of the second quarter of 2026. While the MOU reflects a shared intent to proceed, there can be no assurance that a joint venture will ultimately be formed, that it will be completed within the anticipated timeline, or that it will prove commercially viable.

The FSR converts quartz directly into fumed silica in a single-step, chemical-free process, eliminating the use of hazardous reagents and avoiding the generation of toxic by-products.

If the joint venture is finalized, delivery and commissioning of the plant are expected within approximately twelve months. Management believes that successful commissioning would support the deployment of additional plants of similar or larger capacity, positioning the technology as a repeatable industrial solution rather than a one-off installation.

“Our objective is not simply to build one plant, but to establish a commercial model that can be reproduced,” Tourillon added. “This initial project for the joint venture will demonstrate that our fumed silica process can operate reliably at industrial scale, generate recurring revenues, and support future expansion without requiring HPQ to carry the full capital burden. If successful, it would represent a foundational step toward long-term value creation in advanced materials.”

Industry and Market Context

Fumed silica is a critical industrial material used across a wide range of applications, including cosmetics, pharmaceuticals, food products, paints, coatings, sealants, construction materials. Its role as a thickening, anti-caking, and reinforcing agent makes it essential to product performance, consistency, and manufacturability in high-volume industrial markets.

REFERENCE SOURCES

| [1] | While HSPI remains a wholly owned subsidiary of HPQ Silicon Inc., technology supplier PyroGenesis is in the final stages of exercising its option to acquire a 50% interest in HSPI, as first announced in May 2024.

|

About HSPI the Fumed Silica Reactor (FSR)

As HSPI Technological supplier, PyroGenesis is the exclusive supplier of a plasma-based technology that uses quartz (SiO2) as a raw material to produce commercial-grade fumed silica in a single and eco-friendly process while eliminating the use of harmful chemicals generated by some conventional methods. The FSR requires no additional processes to develop and prepare feedstock, and no intermediary toxic chemical-based processing. The FSR can produce fumed silica from quartz at one physical location.

When compared to some multi-step, traditional processing methods,the expected benefits of our fumed silica reactor process can generally be summarized as follows:

| (1) | Lower capital costs |

| (2) | Lower operating costs |

| (3) | Reduction of CO2 emissions |

| (4) | Reduction in energy footprint |

| (5) | Elimination of purchase and storage requirements for hazardous chemicals |

| (6) | Simplified logistics/shortened production chain due to the single location, single system,

single phase process, and the elimination of feedstock ingredient handling, storage,

preparation/transformation, and transportation |

| (7) | Safer production environment due to absence of dangerous, toxic, or explosive chemicals

|

About HPQ Silicon

HPQ Silicon Inc. is a Quebec-based TSX Venture Exchange industrial issuer (TSX-V: HPQ) focused on innovation in advanced materials and critical process development. In partnership with its research and development partner Novacium—of which HPQ is a shareholder—the Company is advancing next-generation silicon-based anode materials (Gen3) for batteries, commercializing its ENDURA+ lithium-ion cells, and developing breakthrough clean-hydrogen and waste-to-energy technologies, for which HPQ holds exclusive North American rights.

HPQ is also pursuing proprietary technologies to become a low-cost, zero-CO₂ producer of fumed silica and high-purity silicon, with technical support from PyroGenesis Inc. Together, these initiatives position HPQ to capture growth opportunities in the energy storage, clean hydrogen, and advanced materials markets essential to achieving global net-zero goals.

For more information, please visit HPQ Silicon web site.

About PyroGenesis Inc.

PyroGenesis leverages 35 years of plasma technology leadership to deliver advanced engineering solutions to energy, propulsion, destruction, process heating, emissions, and materials development challenges across heavy industry and defense. Its customers include global leaders in aluminum, aerospace, steel, iron ore, utilities, environmental services, military, and government. From its Montreal headquarters and local manufacturing facilities, PyroGenesis’ engineers, scientists, and technicians drive innovation and commercialization of energy transition and ultra-high temperature technology. PyroGenesis’ operations are ISO 9001:2015 and AS9100D certified, with ISO certification maintained since 1997. PyroGenesis’ shares trade on the TSX (PYR), OTCQX (PYRGF), and Frankfurt (8PY1) stock exchanges. www.pyrogenesis.com

Cautionary Note Regarding Forward-Looking Information

This press release contains forward-looking statements regarding HPQ Silicon’s Fumed Silica Reactor project. Such statements reflect management’s expectations on future performance, pilot plant testing, commercialization, financing, and strategic milestones. They involve assumptions about technology, market conditions, financing, permits, supply chains, and economic factors. However, risks—including delays, financing challenges, regulatory changes, competition, commodity prices, geopolitical factors, and market demand—may cause actual results to differ materially.

Readers are cautioned that forward-looking information is uncertain and not guarantees of future performance. Additional risk factors are detailed in HPQ’s Annual Information Form on SEDAR+.

A more detailed cautionary note regarding forward-looking information related to HPQ Fumed Silica is available for download [here].

Further information regarding the Company is available in the SEDAR+ database (www.sedarplus.ca), and on the Company’s website at: http://www.hpqsilicon.com/

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

This News Release is available on the company's CEO Verified Discussion Forum, a moderated social media platform that enables civilized discussion and Q&A between Management and Shareholders.

Source: HPQ Silicon Inc.

For further information contact:

Bernard J. Tourillon, Chairman, President, and CEO

Tel +1 (514) 846-3271

Email: Info@hpqsilicon.com

A photo accompanying this announcement is available at https://www.globenewswire.com/NewsRoom/AttachmentNg/b9c289b6-2986-432b-92b3-7703c5b26e88

Image PR CP Feb 2026

Image: fumed silica, produced by the fumed silica reactor

© 2026 Canjex Publishing Ltd. All rights reserved.