Grand Falls-Windsor, Newfoundland and Labrador--(Newsfile Corp. - January 15, 2026) - First Atlantic Nickel Corp. (TSXV: FAN) (OTCQB: FANCF) (the "Company" or "First Atlantic") notes that its Pipestone XL discovery of awaruite, a rare, naturally occurring nickel-iron-cobalt alloy, is relevant to critical mineral supply chain vulnerabilities outlined in the White House proclamation published January 14, 2026.

The proclamation, titled "Adjusting Imports of Processed Critical Minerals and Their Derivative Products into the United States" states that processed critical minerals and their derivative products (PCMDPs) are being imported into the United States in quantities that may threaten to impair national security. The proclamation identifies nickel and cobalt as essential minerals for critical infrastructure, defense applications, and battery energy storage systems.

The proclamation further notes that, "Even where the United States has domestic mining capacity, such as for cobalt, nickel, and rare earth elements, the United States lacks the domestic processing capacity to avoid downstream net-import reliance."

In response, the Secretary of Commerce recommended that the President "negotiate agreements with foreign nations to ensure the United States has adequate critical mineral supplies and to mitigate the supply chain vulnerabilities as quickly as possible." Canada is considered a "domestic source" under Title III of the U.S. Defense Production Act (DPA) and produces 21 of the 50 minerals designated as critical by the U.S. Geological Survey (USGS), as well as 10 of the 12 NATO defense-critical raw materials1.

USGS Identified Awaruite - A Rare Magnetic Nickel-Cobalt Alloy - as a Potential Solution to Nickel Concentrate Shortages

First Atlantic's Pipestone XL discovery represents the first large-scale reported drilled discovery of awaruite in the Western Hemisphere since the U.S. Geological Survey (USGS) identified this rare magnetic nickel-cobalt alloy as a potential solution to nickel concentrate shortages in its 2012 annual report on nickel.

The USGS stated: "The development of awaruite deposits in other parts of Canada may help alleviate any prolonged shortage of nickel concentrate. Awaruite, a natural iron-nickel alloy, is much easier to concentrate than pentlandite, the principal sulfide of nickel."

Figure 1: Quote from USGS on Awaruite Deposits2

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/6963/280485_11877b5644b768b3_001full.jpg

Awaruite's Magnetic Processing Bypasses Smelter and Permitting Constraints of Conventional Nickel Sources

The White House proclamation emphasizes that "mining a mineral domestically does not safeguard the national security of the United States if the United States remains dependent on a foreign country for the processing of that mineral." Awaruite offers the potential to bypass the processing bottlenecks and challenges associated with conventional nickel sources.

Unlike conventional nickel sulfide deposits, which typically require pyrometallurgical smelting, or laterite deposits, which often rely on high-pressure acid leaching (HPAL) or roasting, awaruite can be processed using magnetic separation and flotation. This process may eliminate certain processing and permitting bottlenecks associated with nickel sulfide or laterite ores. Awaruite concentrate can be shipped directly from mine to refinery, where nickel sulfate (NiSO₄), a critical mineral derivative product, may be produced for the battery cathode manufacturing supply chain.

Awaruite is a naturally occurring, sulfur-free nickel-iron-cobalt alloy with nickel content of approximately 77%3. Its magnetic properties and simple flotation characteristics result in lower electricity requirements and reduced emissions relative to conventional nickel processing methods. In addition, the absence of sulfur reduces the risk of acid mine drainage and certain permitting challenges commonly associated with sulfide mineralization.

Limited North American Smelter Capacity Constrains Nickel Sulfide Processing

According to the August 2025 report "From Rocks to Power: Strategies to Unlock Canada's Critical Minerals for Global Leadership in Energy Storage, EVs, & Beyond," North America currently only has two operational pyrometallurgical nickel smelters: Glencore's Sudbury Smelter and Vale's Copper Cliff Smelter & Refinery, both located in Ontario. Vale's Thompson Smelter in Manitoba was permanently closed in 2018, further constraining processing capacity. The United States currently has no operating domestic nickel smelters. This limited processing capacity represents a key vulnerability identified in the White House proclamation. Awaruite's ability to be processed without smelting may provide an alternative pathway that reduces reliance on constrained or foreign-controlled processing infrastructure.

Awaruite Nickel-Cobalt Concentrate: Direct From Mine to Refinery Without Smelting

Preliminary metallurgical testing at Pipestone XL has returned a magnetic concentrate averaging approximately 1.3% nickel and secondary cobalt in alloy mineralization from large, disseminated, near-surface zones. Ongoing metallurgical work is focused on upgrading this magnetic concentrate by approximately 45-fold, from 1.3% to ~60%, through flotation.

As stated in the August 2025 report "From Rocks to Power" from the Battery Metals Association of Canada4:

"Awaruite is not a sulfide nor an oxide nickel ore but a high-content native nickel-iron ore. Simple beneficiation processes after mining could provide 60% Ni concentrate, ready for leaching for battery cathode purposes and would yield MHP as a by-product. This process would bypass pyrometallurgy or early hydrometallurgy stages and be among the lowest carbon-intensive nickel production sites in the global nickel market."

The Battery Metals Association of Canada has also stated in June 20255:

"A future nickel metallurgical plant could be designed to produce nickel sulfate or even precursors to the cathode active material (pCAM) for NMC batteries. Nickel sulfate can be produced by leaching nickel matte from nickel sulfide concentrates if the facility is a smelter, or it can be easily produced from a hydrometallurgical facility leaching awaruite concentrates."

Section 45X Advanced Manufacturing Production Credit

Section 19 of the U.S. Advanced Manufacturing Production Credit (45X) defines qualifying nickel as nickel that is "converted to nickel sulphate" or "purified to a minimum purity of 99 percent nickel by mass." The ability of awaruite concentrate to be directly converted to nickel sulfate, without intermediate smelting or roasting, may position it favorably within this framework, potentially enabling domestic production of 45X-compliant nickel and cobalt concentrate for the US Battery Manufacturing Supply Chain.

Chromium Identified as Potential Additional Recoverable Mineral

The Company's metallurgical program now includes evaluation of chromium following confirmation of chromite mineralization with elevated chromium content in the awaruite-bearing magnetic concentrate. Chromium has been recovered alongside nickel through Davis Tube Recovery (DTR) magnetic separation testing, and additional metallurgical work is underway to assess the potential to produce a salable chromite concentrate by-product. North America currently lacks sufficient quantities of mined chromium concentrates required for stainless steel and advanced alloy manufacturing. Chromite recovery represents a potential additional critical mineral supply chain opportunity addressed by the Pipestone XL project.

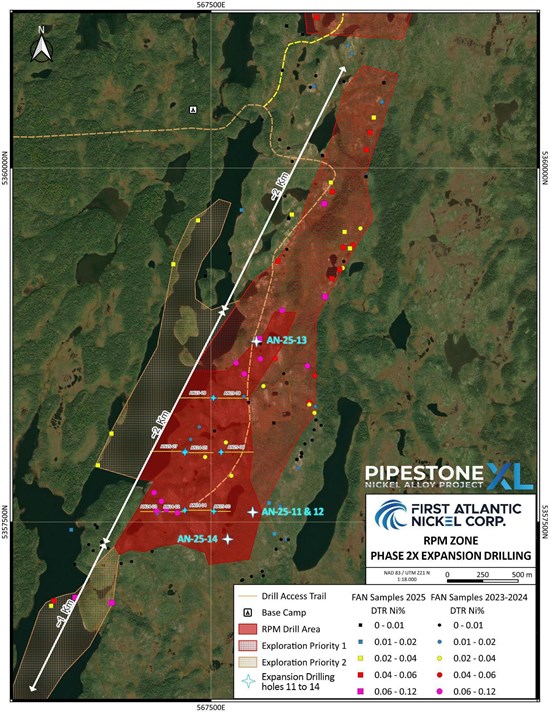

Phase 2X RPM Drilling and Upcoming Pipestone XL Drill Program

The Company anticipates providing updates on drill holes AN-25-11 through AN-25-14 from the RPM Zone Phase 2 program. Following the recent closing of a $2.61 million financing, the company is evaluating various targets for a new winter drill program to further delineate and expand the Pipestone XL Nickel Alloy Project.

RPM ZONE DRILLING SUMMARY

Table 1: RPM Zone - Complete Intervals for All RPM Drill Holes Reported to Date

| Drill Hole | Zone | Section | From (m) | To (m) | Interval (m) | DTR Ni (%) | Mag Conc Ni (%) | Mass Pull (%) |

| AN-24-02 | RPM | S1 | 11.0 | 394.1 | 383.1 | 0.13 | 1.37 | 9.50 |

| AN-24-03 | RPM | S1 | 18.0 | 234.0 | 216.0 | 0.11 | 1.32 | 9.12 |

| AN-24-04 | RPM | S1 | 12.0 | 378.0 | 366.0 | 0.14 | 1.46 | 9.53 |

| AN-24-05 | RPM | S2 | 6.0 | 357.0 | 351.0 | 0.12 | 1.47 | 8.21 |

| AN-25-06 | RPM | S2 | 5.65 | 453.0 | 447.35 | 0.11 | 1.27 | 9.02 |

| AN-25-07 | RPM | S2 | 9.0 | 495.0 | 486.0 | 0.09 | 0.97 | 9.60 |

| AN-25-08 | RPM | S3 | 11.0 | 491.0 | 480.0 | 0.12 | 1.35 | 8.79 |

| AN-25-09 | RPM | S3 | 9.0 | 483.0 | 474.0 | 0.08 | 0.93 | 9.00 |

| AN-25-10 | RPM | S1 | 8.0 | 236.0 | 228.0 | 0.15 | 1.44 | 10.48 |

| AN-25-11 | RPM | S1 East | TBA - Eastern Expansion |

| AN-25-12 | RPM | S1 East | TBA - Eastern Expansion |

| AN-25-13 | RPM | S4 | TBA - 400m Northern Extension |

| AN-25-14 | RPM | S0 South | TBA - 200m Southern Step-Out |

DTR nickel percentage is calculated by multiplying the mass pull (%) by the magnetic nickel concentrate grade (%). This number represents the proportion of nickel recoverable through magnetic separation and is not equivalent to a standard assay result. Every 3-meter interval throughout each drill hole was processed using this metallurgical method. DTR results may vary depending on equipment settings and ongoing technological advancements.

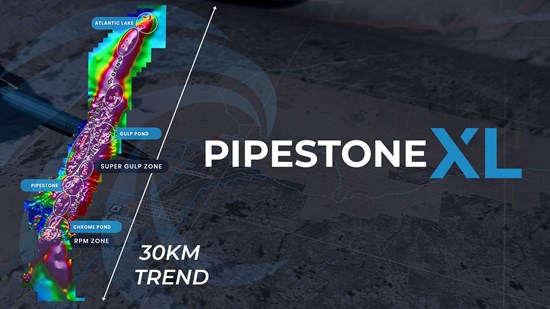

Figure 2: Pipestone XL Alloy Project showing target zones along a 30km trend over total magnetic intensity (TMI).

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/6963/280485_11877b5644b768b3_002full.jpg

Figure 3: Aerial image looking over RPM zone extension highlighting flat undulating terrain typical at the Pipestone XL nickel alloy project.

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/6963/280485_11877b5644b768b3_003full.jpg

Figure 4: RPM Zone Area Map Showing Phase 2X Expansion Drill Hole Locations and Surface Sample DTR Nickel Results Outlining the Priority Target Areas.

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/6963/280485_11877b5644b768b3_004full.jpg

Investor Information

The Company's common shares trade on the TSX Venture Exchange under the symbol "FAN", the American OTCQB Exchange under the symbol "FANCF" and on several German exchanges, including Frankfurt and Tradegate, under the symbol "P21".

Investors can get updates about First Atlantic by signing up to receive news via email and SMS text at www.fanickel.com.

Disclosure

Adrian Smith, P.Geo., a director and the Chief Executive Officer of the Company is a qualified person as defined by NI 43-101. The qualified person is a member in good standing of the Professional Engineers and Geoscientists Newfoundland and Labrador (PEGNL) and is a registered professional geoscientist (P.Geo.). Mr. Smith has reviewed and approved the technical information disclosed herein.

Analytical Method & QA/QC

Samples were split in half on site, with one half remaining in the core box for future reference and the other half securely packaged for laboratory analysis. The QA/QC protocol included the insertion of blanks, duplicates, and certified reference material (standards), with one QA/QC sample being inserted every 20 samples to monitor the precision and accuracy of the laboratory results. All analytical results successfully passed QA/QC screening at the laboratory, and all Company inserted standards and blanks returned results within acceptable limits.

Samples were submitted to Activation Laboratories Ltd. ("Actlabs") in Ancaster, Ontario, an ISO 17025 certified and accredited laboratory operating independently of First Atlantic. Each sample was crushed, with a 250 g sub-sample pulverized to 95% - 200 mesh. A magnetic separate was then generated by running the pulverized sub-sample through a magnetic separator which splits the sub-sample into magnetic and non-magnetic fractions. This involves running a 30 g split of the pulp through a Davis Tube magnetic separator as a slurry using a constant flow rate, a magnetic field strength of 3,500 Gauss, and a tube angle of 45 degrees to produce magnetic and non-magnetic fractions.

The magnetic fractions are collected, dried, weighed and the magnetic fraction is fused with a lithium metaborate/tetraborate flux and lithium bromide releasing agent and then analyzed on a wavelength dispersive XRF for multiple elements including nickel, cobalt, iron and chromium. The magnetically recovered nickel grade was then calculated by multiplying the XRF fusion nickel value by the weight of the magnetic fraction and dividing by the total recorded feed weight or magnetic mass pulled from the sample.

True widths are currently unknown. However the nickel bearing ultramafic ophiolite and peridotite rocks being targeted and sampled in the drilling programs at the Pipestone XL Project are mapped on surface and in drilling as several hundred meters to over 1 kilometer wide and approximately 30 kilometers long.

About First Atlantic Nickel Corp.

First Atlantic Nickel Corp. is a mineral exploration company focused on the discovery and development of awaruite, a rare, naturally occurring nickel-iron-cobalt alloy, at its 100%-owned Pipestone XL Project in Newfoundland. The project spans the 30-kilometer Pipestone Ophiolite Complex, where multiple zones contain awaruite (nickel-cobalt) mineralization along with secondary chromium. Awaruite's magnetic properties enable processing through magnetic separation, potentially eliminating the need for conventional smelting or high-pressure acid leaching while reducing dependence on foreign-controlled processing infrastructure.

Forward-looking statements:

This news release may include "forward-looking information" under applicable Canadian securities legislation. Such forward-looking information reflects management's current beliefs and are based on a number of estimates and/or assumptions made by and information currently available to the Company that, while considered reasonable, are subject to known and unknown risks, uncertainties, and other factors that may cause the actual results and future events to differ materially from those expressed or implied by such forward-looking information.

Forward-looking information in this news release includes, but is not limited to, statements regarding: the timing, scope, objectives and results of the Company's exploration and drilling programs at Pipestone XL (including the Phase 2X expansion drill holes, the timing of updates for drill holes AN-25-11 through AN-25-14, and any planned winter drilling program); the potential to expand the drill-confirmed dimensions of the RPM Zone and the broader RPM Zone target; the potential size, continuity and extension of awaruite-bearing mineralization and associated chromite/chromium mineralization; the interpretation and application of DTR results and other metallurgical test work; the expected performance and viability of magnetic separation and flotation, including the ability to upgrade magnetic concentrate; the potential for awaruite concentrate to be transported to and processed at third-party facilities and/or refined into nickel sulfate ; the potential relevance of Section 45X and other U.S. critical mineral initiatives to downstream processing scenarios; and the Company's ability to advance its projects, obtain financing and execute its business plans.

Forward-looking information is based on, among other things, assumptions regarding: the continuity of geology and mineralization suggested by drilling, sampling, and surface work to date; DTR recoverability results and metallurgical recoveries remaining comparable under similar processing conditions; magnetic separation performance continuing to be consistent with test results; the availability of drill rigs, contractors, services, personnel, supplies, and equipment; the receipt of required permits and approvals within expected timeframes; prevailing and future commodity prices, market conditions, and demand; and the Company's ability to obtain financing on reasonable terms to fund planned exploration and metallurgical programs.

Readers are cautioned that such forward-looking information are neither promises nor guarantees and are subject to known and unknown risks and uncertainties including, but not limited to, risks inherent in mineral exploration; variations in geology, grade and recoverability; metallurgical and processing risks (including variability in DTR and flotation results and scale-up risk); the risk that concentrate may not be suitable for or accepted by third-party processing/refining facilities on acceptable terms; changes in laws, regulations or government policies (including the interpretation or application of Section 45X or other U.S. critical mineral initiatives); capital market and commodity price volatility; financing risks; environmental and permitting risks; operational risks; and delays in obtaining approvals. Additional factors and risks including various risk factors discussed in the Company's disclosure documents which can be found under the Company's profile on http://www.sedarplus.ca. Should one or more of these risks or uncertainties materialize, or should assumptions underlying the forward-looking statements prove incorrect, actual results may vary materially from those described herein as intended, planned, anticipated, believed, estimated or expected.

The Company is presently an exploration stage company. Exploration is highly speculative in nature, involves many risks, requires substantial expenditures, and may not result in the discovery of mineral deposits that can be mined profitably. Furthermore, the Company currently has no mineral reserves on any of its properties. As a result, there can be no assurance that such forward-looking statements will prove to be accurate, and actual results and future events could differ materially from those anticipated in such statements. The Company undertakes no obligation to update forward-looking information, except as required by applicable securities laws.

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

1 https://connect2canada.com/wp-content/uploads/2025/01/critical-minerals.pdf

2 https://d9-wret.s3.us-west-2.amazonaws.com/assets/palladium/production/mineral-pubs/nickel/mcs-2012-nicke.pdf

3 https://www.sciencedirect.com/science/article/abs/pii/S0892687522003648

4 https://transitionaccelerator.ca/wp-content/uploads/2025/08/From-Rocks-to-Power-Nickel.pdf

5 https://netzeroindustrialpolicy.ca/wp-content/uploads/2025/07/BMAC_TA_EFL_Western_Canadian_Battery_Value_Chain.pdf

To view the source version of this press release, please visit https://www.newsfilecorp.com/release/280485

© 2026 Canjex Publishing Ltd. All rights reserved.